Forms For Concrete Work

Forms For Concrete Work

General

To use concrete in making any object, it is necessary that the material, while in a plastic state, be confined in e form or mold which has an interior surface and shape corresponding to that of the object which is to be made. Therefore forms or molds are the receptacles in which a concrete mixture is placed immediately after mixing so that when hardened the concrete will assume the shape desired or intended.

Forms for concrete steps. Care should be taken to have the ground well compacted where steps are to rest. The side walls, or ramps, can be made first or last as desired. A 1:2:4 concrete mixture should be used throughout. The concrete should be wood floated on the step treads instead of finished with a steel trowel, Using a wood float will give a surface that will provide a good foothold.

Types Of Forms

Forms for concrete may be made wholly of wood, or of wood metal lined, or wholly of metal, or in some cases of plaster of Paris. By far the greater number of forms used in concrete work are made of wood. Cast iron and steel forms or molds are used in connection with machines that e concrete block, concrete brick, and similar concrete

• objects that are made wholly or in part by compressing the concrete mixture. Also, metal molds or wood molds metal lined are used in cases where it is desired to give the concrete a particularly smooth surface. The shape of forms is governed entirely by the shape of the object which it is desired to build. Form work is a very important step in the use of concrete for any building construction. No concrete object can be truer in shape or form than the mold in which it is made, and for small objects or those which are to be somewhat ornamental, careful work done on forms is well repaid in the satisfaction given by the finished concrete work.

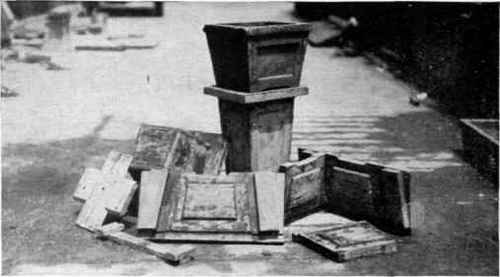

Forms removed from a concrete pedestal to illustrate both forms and finished object.

Some Form Requirements

When wood is used for concrete forms it is necessary that it be straight-grained material free from warp, knots and other imperfections which would leave their imprint on the finished concrete surface, for concrete is very faithful in reproducing both the perfection as well as the imperfection or irregularity of forms. For ordinary concrete work such s foundation and surfaces which are not to be permanently exposed to view and hence which need not have that smooth, regular finish otherwise desirable, common grades of lumber may be used provided the material has the required strength. Spruce, Norway pine and southern pine are used largely in such cases. Whether the lumber shall be planed on one side and two edges depends somewhat on the nature of the work. A planed surface can be treated so that little concrete will stick to it, while planed or jointed edges of form boards make tight-fitting forms which prevent joint markings on the work and any leakage of cement and water from the concrete. White pine is often used for small objects, especially where e ornamental is to be added, because it is easy to work. Except in such cases, however, it is usually a more expensive form material than is required. Cast iron, sheet steel, or wood covered with galvanized iron or sheet steel is used where an extremely smooth finish is desired without further treatment after forms have been removed from the work. Forms made of metal can be cleaned more easily than wood forms and can be used a greater number of times.

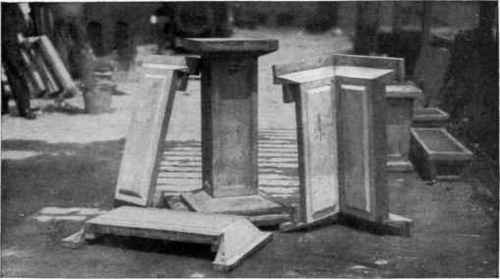

Forms removed from vase and pedestal in which they were made.

One of the pleasurable aspects of concrete work to many is that it requires that there be skill in carpenter work. It gives a person the opportunity to display individuality in more ways than one. Forms should be carefully planned so that there may be no difficulty in assembling the pieces nor in taking them from the object when finished. Careful planning will also result in considerable saving of lumber because much unnecessary cutting and waste will be avoided. Wherever possible, forms should be planned so that for use they can be assembled with few and simple fastenings. Screws and clamps to hold them together while concrete is being placed-where they can be used-are preferable to nails or other permanent methods of assembling.

its another example of concrete pedestal showing the forms in which it was made.

Air-seasoned lumber is better than kiln-dried for ordinary form purposes, but for small objects and especially for objects that are to have some ornament, kiln-dried lumber should be used and the lumber should be given special treatment before assembled the first time so as to prevent changes in its shape or form due to swelling and warping because of alternate wet and dry conditions in use. For many of the small objects that will be illustrated and described later, clear, kiln-dried white pine will be the best lumber to use for forms.